Air Cooled Heat Exchangers

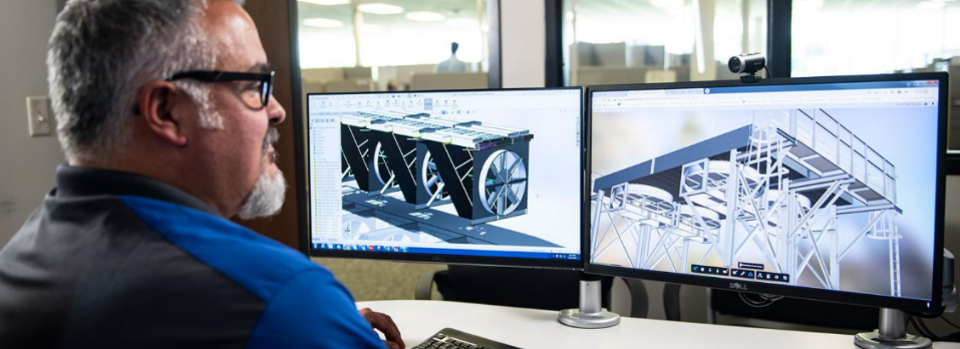

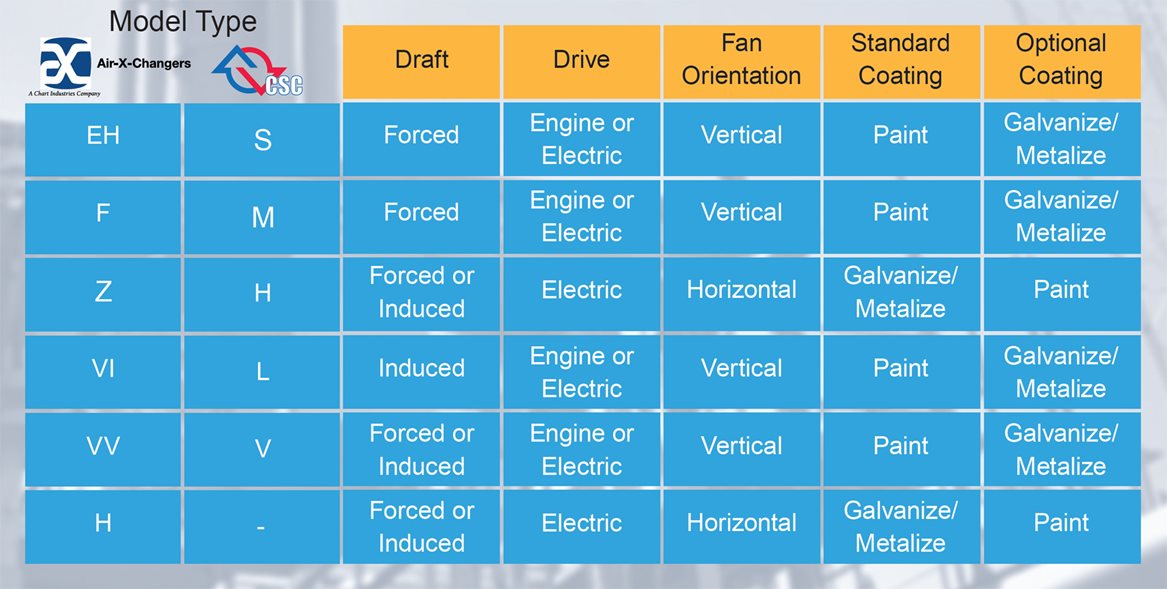

Through the Hudson Products, Air-X-Changers, Smithco, Hammco and Cooler Service Company brands, Chart has brought together trusted leaders to provide heat transfer solutions across upstream, midstream, downstream, refinery, petrochemicals, power and others.

-1134x670.jpg)

.jpg?ext=.jpg)

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team